In the dynamic environment of a startup, especially very early stage startups, the internal supply chain is often neglected. This oversight can quickly lead to underwhelming product quality, inefficient use of scarce resources, and poor documentation. Full control of the internal supply chain is essential to minimize risk and prepare for upscaling. The Fast Forward Production database application is designed to evolve with your company, together with its manufacturing processes, the suppliers, and the product. It perfectly aligns with agile and lean development principles while ensuring accountability and efficiency.

- Track development, prototyping, and (early) manufacturing in one system.

- Generate data for optimizations regarding cost, efficiency, reliability, and yield.

- Lean but complete documentation for failure analysis and potential transfer/outsourcing of parts of the manufacturing.

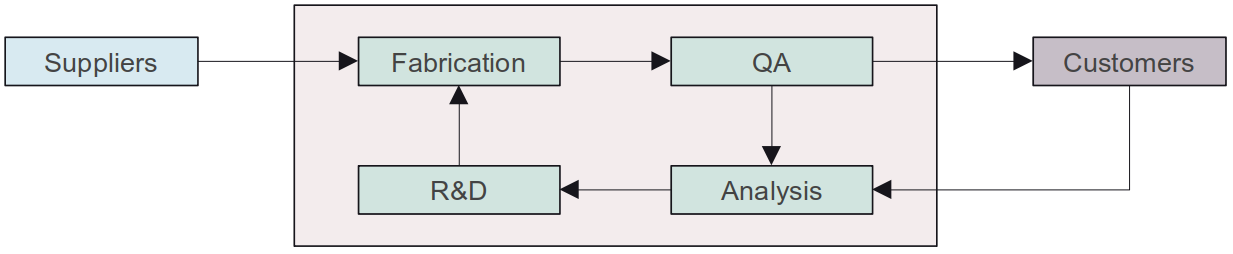

The Internal Supply Chain in a Startup

The internal supply chain in a startup mirrors the R&D processes of established companies, with one key difference: startups often sell the products long before development is finalized and approved for production. While this accelerates development and allows to gather customer feedback early, it may lead to significant resource challenges when products require post-delivery service.

- Strong focus on development, with a fast feedback loop.

- Few suppliers, very few customers, scarce resources.

- Many iterations and variations to optimize the product and mature the processes.

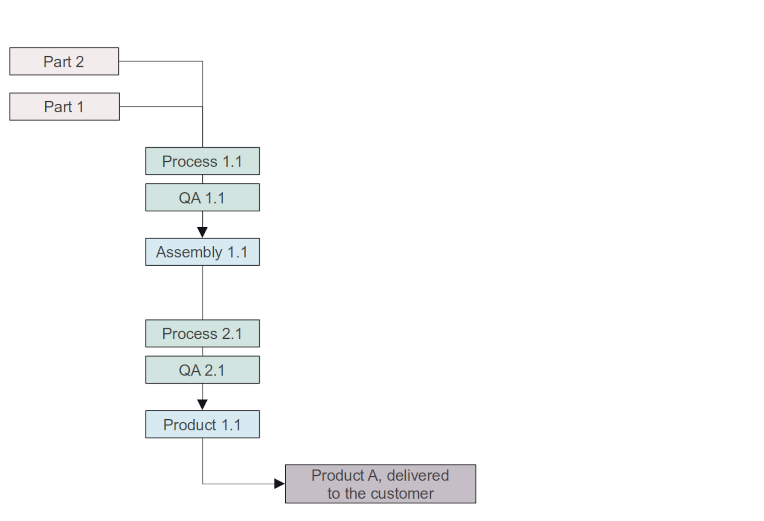

Mapping the Evolution of the Internal Supply Chain

Starting from a rudimentary understanding with placeholders for processes, the supply chain matures into robust manufacturing workflows with clearly defined steps, relevant specifications, and comprehensive quality assurance. With each iteration and increasing knowledge the supply chain becomes more mature.

- MVP Stage: Initial, untested product with high potential but needing optimization.

- Process Improvements: Implement enhancements to streamline production.

- Quality Assurance: Integrate consistent QA measures for all steps.

- Alternative Supplier: Identify and switch to alternative, lower-cost suppliers.

- Detailed Tracking: Monitor the manufacturing of individual parts and process runs, leading to consistent product quality.

Know your Product Versions

Maintain detailed records of product fabrication within these evolving processes, accommodating changes in input and output specifications.

- Component Tracking: Identify which components were used for each product version.

- Process Tracking: Record the processes applied to each product version.

- Comprehensive History: Track the complete lifecycle, including returns, repairs, and recycling of (sub-) products, and its current location.

- Dependency Mapping: Maintain a full dependency tree of all (sub-) products.

- Inventory Management: Keep an accurate account of inventory levels and sub-products in the pipeline.

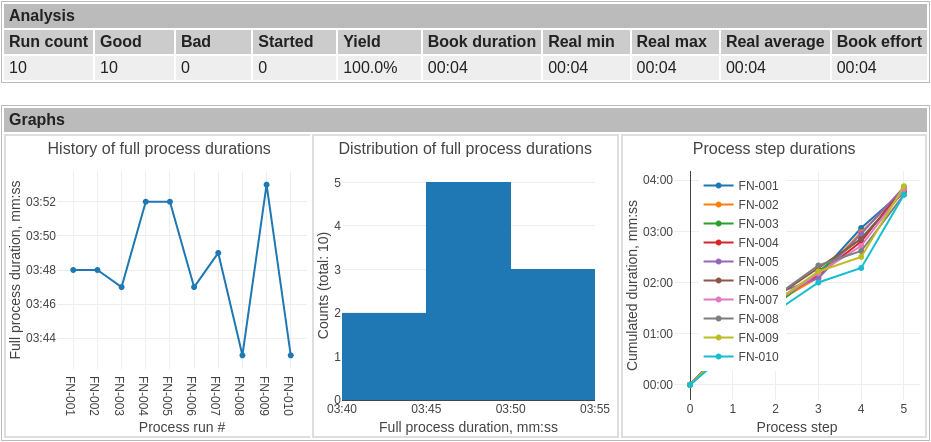

Data-Driven Optimization

Collect data from all individual process runs to optimize efficiency, reliability, yield, and time requirements. Evaluate the entire manufacturing process chain as a whole as well as individual steps of a single process to gain a comprehensive understanding and identify potential risks.

Database Application Details

- Web-Based Interface:

- View, add and edit processes, parts, and products seamlessly.

- Perform and document the actual manufacturing and quality assurance.

- User Roles and Policies: Ensure proper use through defined user roles and policies.

- Third-Party Integration: Easily integrate with external hardware and software, including our MVP3000 framework.

- Open Database: Benefit from an open MySQL/MariaDB database with no vendor lock-in.

- Data Export: Export data for analysis in various environments, including Python.

Contact Us

Partner with us to leverage our expertise, to achieve your vision efficiently and effectively.

contact@production3000.com